The Challenge

Back in the early 1970’s the Carbon Black industry was dealing with a very costly issue that they were having with the rail car and over the road trailer hatch covers and the dump valve covers. At the time, the covers were made of metal and since the carbon black material is very caustic, the covers were deteriorating. When a worker would slam the metal covers closed, pieces of the deteriorated metal would fall off and contaminate the entire load of carbon black material. The result was large amounts of money was spent to ship and reprocess the material.

The Solution

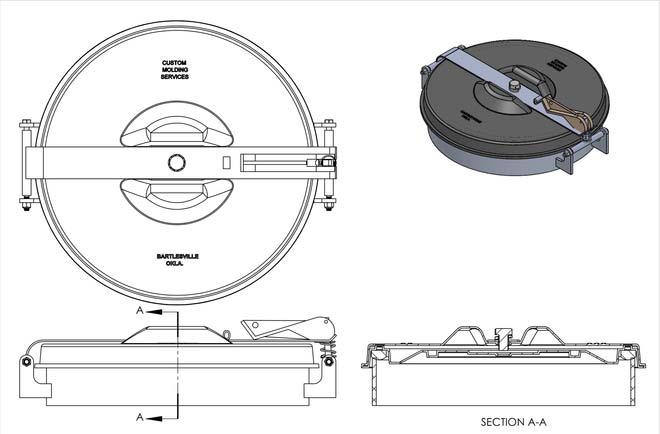

As a result, Custom Molding Services, Inc. designed a hatch cover and dump valve cover made from polyurethane, which is UV protected and will not deteriorate in the presence of the carbon black material.

In 1973 Custom Molding Services, Inc. began production of both the Hopper Car hatch covers and dump valve covers as well as the hatch covers and dump valve covers for the over the road semi-trailers.

"the Carbon Black Industry still uses these covers today"

The Future

Custom Molding Services, Inc. in fact took the next step in making the covers even more resistant to the caustic carbon black material by making all of the metal components out of stainless steel.

Even though it has been over forty years, the Carbon Black Industry still uses these covers today and many of the covers out in the field have been used for many years.